Frequently Asked Questions

Frequently Asked Questions about Spalted Wood and Spalted Maple

-

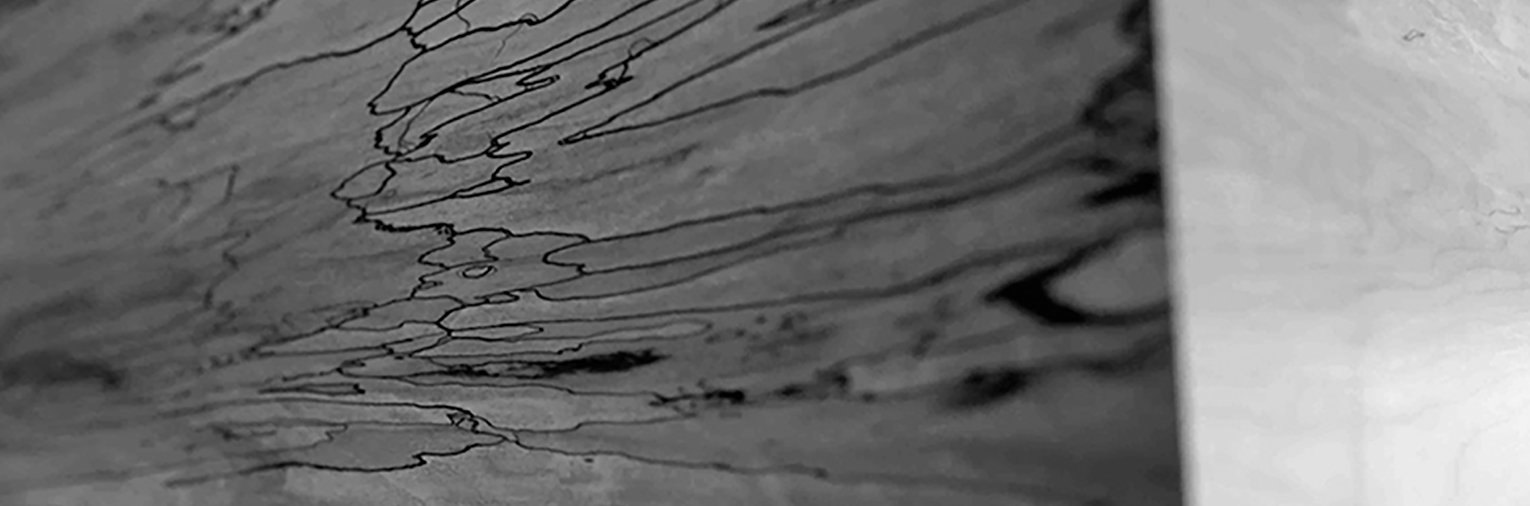

Spalted maple is the term used for regular maple wood that has been colonized by various fungi and has started the process of decomposing back to soil. In that process the fungi create colors, lines and textures that are true wonders of nature -clean yet unpredictable, mesmerizing in their semblance of coordination, and beautifully alive in their lack of uniformity.

-

Historically, due to its scarcity, spalted maple has been considered a very choice material by artisans, reserved for use in relatively small scale, high-end woodworking projects. Whether it was an intricate veneer marquetry inlay project from the 1700s, or a custom built guitar from 1970, people have revered spalted wood as something truly special/unique for hundreds of years.

-

There are many factors that come into play to determine how long it takes to spalt wood. Essential factors include moisture, temperature and light. It typically takes 2-4 years for new wood to be transformed into the magic that is spalted wood.

-

Spalted maple can offer a bright rainbow of pigmentations due to the various fungi which cause the spalting. The winding lines can be black, brown or even reddish, while the wood can turn a darker yellow, or be bleached white. Shades of pink and gray may also reveal themselves.

-

We have used many metaphors to describe the value of spalted maple - from “a diver finding a pearl in an oyster” to “stumbling on truffles in a forest.” In short, spalted maple is rare, beautiful and unique - and therefore valuable. However, with Vermont Wildwoods proprietary spalting method we are able to more consistently produce beautiful spalted maple products at a more affordable price point.

-

The Sugar Maple is a hardwood and is more dense in the spectrum of most commercially available North American hardwoods. It is a strong and stiff wood. However, the fungi responsible for creating such beauty also decrease the strength of maple in the decay process. But due to the fact all of our material is sliced into veneer and glued to a solid core material to make spalted plywood - the decrease in density is not an issue for the strength of the final product.

-

Spalted maple is not a species of maple, but is rather any type of maple that has been allowed to begin initial stages of decay. The partial decay gives the wood distinctive dark lines and coloring that is called spalting. The spalting process takes approximately two years and when sold, the decay is halted as the wood is dried in a wood kiln. The resulting veneer is hand selected to ensure it is usable for its intended need.

-

For most healthy people, spalted maple in no way causes any more respiratory or skin irritation than any other North American hardwood. Though like any wood, some people may find exposure to spalted dust to be a minor health annoyance.

-

Spalted wood is in no way a mold. The organisms responsible for spalting wood are harmless local naturally occurring Vermont fungi.

-

It should be noted that although spalted maple is the result of fungus and decay, the products made from spalted wood are not dangerous to consumers. Once the fungus has dried out, it dies and offers no threat either to the wood or to humans.

-

In order to spalt, wood needs high moisture, darkness, and heat. Once you remove any of those three items, the spalting process stops. All of our products are properly kiln dried and the moisture is removed which stops the spalting process.

-

At this time we believe we are the only company in the world that is intentionally spalting maple to produce spalted veneer and plywood. There are other companies who sell spalted wood, but there are none who intentionally spalt it.

-

At our Vermont facility we only age the wood. We have off-site manufacturing partners who slice the veneer for us and produce the plywood.

-

The minimum purchase amount for our spalted maple veneer is 200sf. The minimum purchase amount for spalted maple plywood is 10 sheets. If your order volume falls below either of these, please contact us. There is no minimum order amount for spalted maple paper backed veneer sheets.

-

Our veneer is sold either as a random plank blend; which is a blend of light, medium and heavily spalted maple veneer, book match, or book and swing.

-

We ship all orders via LTL common carrier motor freight. All veneer is crated and shipped in one of the strongest boxes in the business. We use ¾” plywood top and bottoms and solid wood framing material for the sides.

-

For veneer orders the lead time is approximately four weeks. Veneer doesn’t ship until a 50% deposit has been received. Plywood lead time ranges from 8-10 weeks depending on whether you’re purchasing finished or unfinished plywood.

-

Yes, if you are a designer, please order samples through Material Bank.

For all other sample requests, please use the form on our website and we’ll be in contact with you.

-

Yes, spalted maple veneer is more fragile than conventional veneer, due to the decomposing that occurs during our controlled spalting process. We recommend that anyone handling spalted maple veneer use caution and be prepared to utilize repair tape to hold together any cracks, splits, or tears.

-

Conventional maple is described as having a fine, uniform texture with generally straight grain, creamy color and generic uniformity. In contrast, spalted maple has lines and textures that are true wonders of nature - clean yet unpredictable, mesmerizing in their semblance of coordination, and beautifully alive in their lack of uniformity.

-

Yes, we will have spalted beech available in late 2024.

-

No. Each bundle of veneer is 100% unique. While you will see similar themes across all bundles, no two leaves are the same.

-

Please contact us if there is a specific look needed for your project. For our standard orders, we select the veneer after having a conversation with you to best meet the specifications.

-

After the logs have aged to perfection we saw them into lumber. At the sawmill we grade the lumber and select what will be sliced into veneer. At that veneer mill the lumber is passed over a stationary blade. Each time the board is passed over the blade a single piece of veneer is sliced off the board. Each board is sliced into approximately 60 pieces of veneer.

-

The veneer ranges from 4”-12” wide with an average width of approximately 7” wide.

-

An individual piece of veneer is called a leaf of veneer.

-

Approximately 60

-

Our veneer ranges in lengths from 4’-9’+, the average length is 8’

-

We slice our veneer at 1/42”(25/1000”) thickness

-

We slice our veneer at 1/40”(25/1000”) thickness - the standard thickness in the hardwood veneer industry.

-

We sell loose leaf veneer as well as paper backed veneer sheets.

-

Very specialized machinery is used to spread just the right amount of glue on the edge of the veneer and each glued piece is fed through a machine that applies just the right amount of pressure to two glued edges. Think writing your name on a grain of rice - this is the degree of precision required for this process.

-

Currently we can produce plywood 4’ wide x 9’ long. We are currently aging maple veneer logs to be able to produce 10’ long spalted maple veneer and plywood.

-

We can produce every thickness of plywood available in the market from ⅛” bendable plywood up to 1” and thicker for special projects.

-

If the core is available in the US we have access to it.

-

Typically most clients want our spalted plywood with spalted veneer on just 1 side with what is called a ‘mill-option backer’ on the backside, but we can certainly put spalted veneer on both sides.

-

Every panel we produce is sanded. Typically 150 grit sandpaper is used in the wide belt sander to produce an even smooth panel that is ready to be finished by your team.

-

We will do our best within the limits of our inventory to work with you to produce the sizes you are looking for.

-

We do offer a UV cured prefinished product in the sheen of your choice. It can be either clear or tinted with the color of your choice.

-

The gloss range is from satin to high gloss.

-

We do not recommend that you use our products for any exterior applications.

-

Yes, we have recently launched a spalted maple engineered flooring product. Please see the engineered flooring specification page for details.

-

Distinguishing Traits: Irregular lines resembling ink drawings producing a marbled effect.

Color: White to brown with occasional shades of black, gray or pink.

Distribution: Primarily temperate regions in the Northern Hemisphere.